Are you ready for Product Realization?

![]() Companies often rush into production with an immature concept, trying to get ahead of the competition or meet unrealistic customer promises. Rushing into product realization too soon invariably leads to downstream failures that ultimately cost the team time and money. When teams move into product realization, the cash flow required increases dramatically: more people have to be hired, non-recurring engineering costs accumulate, and materials have to be purchased. It is better to spend an extra month getting ready when your burn rate is $10, 000 per month than to spend an extra month in piloting when your burn rate is 10 times that amount. While it is tempting to “just get started and figure it out later,” teams need to ask themselves the hard questions about their readiness before committing the resources and capital to start production.

Companies often rush into production with an immature concept, trying to get ahead of the competition or meet unrealistic customer promises. Rushing into product realization too soon invariably leads to downstream failures that ultimately cost the team time and money. When teams move into product realization, the cash flow required increases dramatically: more people have to be hired, non-recurring engineering costs accumulate, and materials have to be purchased. It is better to spend an extra month getting ready when your burn rate is $10, 000 per month than to spend an extra month in piloting when your burn rate is 10 times that amount. While it is tempting to “just get started and figure it out later,” teams need to ask themselves the hard questions about their readiness before committing the resources and capital to start production.

Companies often rush into production with an immature concept, trying to get ahead of the competition or meet unrealistic customer promises. Rushing into product realization too soon invariably leads to downstream failures that ultimately cost the team time and money. When teams move into product realization, the cash flow required increases dramatically: more people have to be hired, non-recurring engineering costs accumulate, and materials have to be purchased. It is better to spend an extra month getting ready when your burn rate is $10, 000 per month than to spend an extra month in piloting when your burn rate is 10 times that amount. While it is tempting to “just get started and figure it out later,” teams need to ask themselves the hard questions about their readiness before committing the resources and capital to start production.

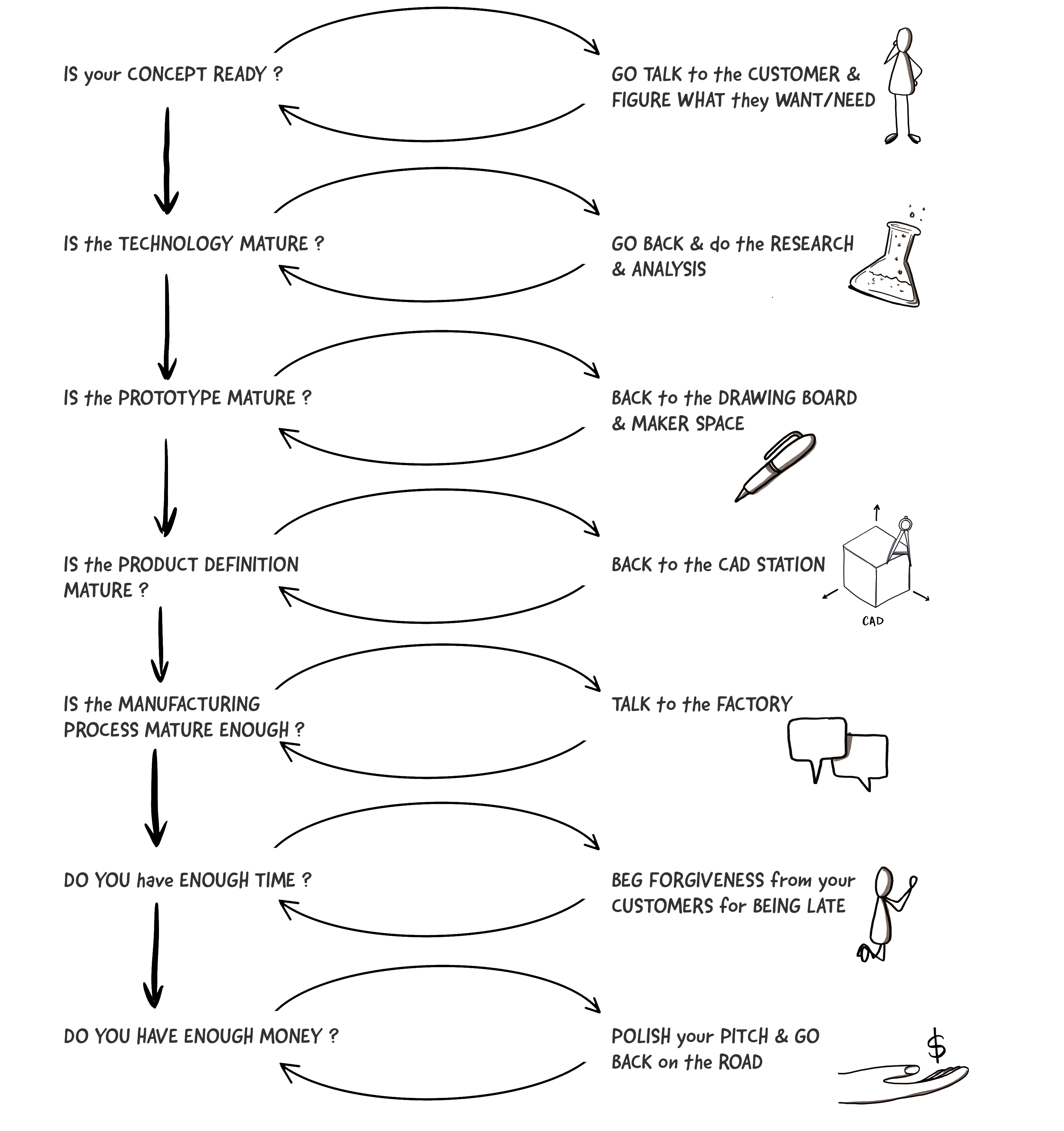

Is your design concept ready? Does it meet the customer’s needs at a reasonable price point? Does the product have a viable business model?

Is the technology used in the product mature enough? Has the team ensured new untested technology will perform reliably? Does any of the technology have any fundamental reliability or quality flaws?

Is the prototype mature enough? Is the prototype a true engineering prototype that represents all of the production-intent details?

Is the product definition mature enough? Has the team documented the product so it can be transferred to the factory and be built to specifications?

Are the manufacturing processes mature enough? Have any new manufacturing process technologies been matured and shown that they can operate at full rates?

Do you have enough time? Have you accurately assessed the time required to get the product ready for production or are you going to be late?

Do you have enough cash on hand? Have you thought through the cost to do the necessary pilot runs and the actual cost to launch the product?

Have you addressed all of the readiness risks? If you are going into piloting with a less than mature product, have you created a risk management plan?